News

CNC Programmer/Setup

CNC Programmer, setup & operate CNC vertical mills – must have good organizational and planning skills, good blueprint reading skills, in depth knowledge of CNC codes, the ability to produce efficient cost effective CNC programs, an understanding of fixture design, extensive knowledge of machining, strong math skills, good communication and problem solving skills.

Education - High school or GED

Experience – 5 –7 year min.

1st shift

send resume to: info@trebliginc.com

phone: 864-277-4882

Opportunities for employment

We are looking for the following:

Manual Machinist: Must be able to read blueprints, set-up & operate mills, lathes and grinders

in a job shop environment.

CNC Programmer/Set-up person: Familiar with Fanuc controls, also be able to handwrite programs from prints.

The power of women in the workplace

After Ronnie suffered a serious heart attached in 1991, his wife, Estlean Cook, knew she had to make a choice-sell the business they jointly owned or take over the management herself. Ronnie's quadruple bypass surgery meant he had to be out of the business for an exteneded period of time and would probably never return to the stressful day-to-day management of the 20 year old Greenville manufacturing facility.

Cook took management control of the facility, with an impressive clientele of companies like Michelin, Ross Controls, Stone Air WABCO and Lockheed. And she is successful, through a skillful use of trained and experienced consultants and personal determination. "It was the right thing to do," said Cook, "and it pushed me to find out that I could do it."

Cook believes that being a female entrepreneur in a non-traditional manufacturing role stands out from the crowd and is remembered much more easily. She admits that convincing some of her seriousness was difficult, but the problem has subsided over the years as she has proved herself to her customers.

The Competitive Review, Fall 2003

ISO 9001:2000 Certification

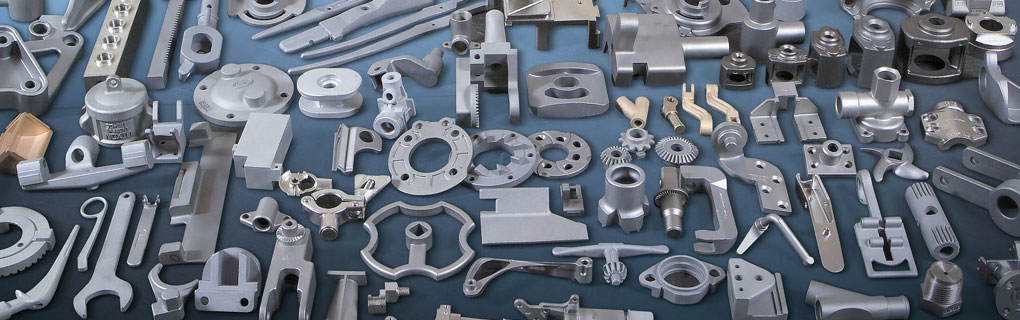

Treblig, Inc., a Greenville, SC-based manufacturer, announces today that it has earned ISO 9001:2000 certification. Treblig, a provider of precision machining, turning and milling services, is only one of a handful of female-owned manufacturers to earn certification to this international quality management standard. Faced with budget constraints and a strenuous application and implementation process, Treblig contacted the South Carolina Manufacturing Extension Partnership (SCMEP) to assist with a comprehensive quality assurance program. SCMEP helped Treblig secure a grant from the U.S. Department of Agriculture/Rural Development Agency and provided assistance to push the certification process through in less than six months.

The ISO 9001:2000 standard outlines the requirements for a quality management system for use by organizations to meet customer requirements and provide better customer satisfaction. SCMEP acted as the project manager for the certification process. As a non-profit organization that provides consulting and implementation services to manufacturers statewide, SCMEP was able to save Treblig six months or more in obtaining ISO certification and over $20,000 on the entire registration process.

"For almost 10 years, we've worked with SCMEP on various projects," said Estlean Cook, president of Treblig, Inc. "Over the years, SCMEP has helped Treblig reduce production costs, increase efficiency, and eliminate waste, so it was only natural that we contact the organization to assist us with this rigorous quality assurance certification program. SCMEP brought expertise and valuable input. We estimate it would have taken much longer and cost us much more to achieve ISO conformance without SCMEP's guidance."

Southeast Machinery & Industrial News, July 2003